Using battens instead of studs for a lighter tiny house wood frame. Is it strong enough?

ˬ˯vᐯ˅ˇ⌣ᘁ᥎ᨆ⏝ ࡍ ⩗ᨆ⌣˘ˬ᥎ᐯᨆ⌣ᘁ⩗ᨆࡍ˯

This post is from Mésange, my weekly ‘popup’ newsletter, from October 2022 to March 2023. < Previous | Next >

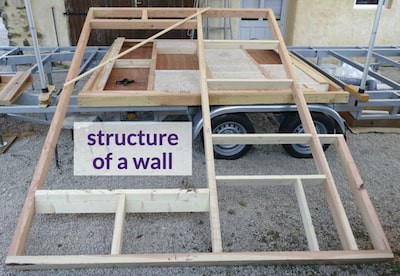

I started to build the wood skeleton of Paññā, our tiny house lab, using standard Douglas fir studs of 5 × 10 cm (2 × 4 in). But I quickly realized that such a wood frame was too heavy.

Here I tell you my adventures to make the wood frame two to three times lighter.

A standard wood frame feels too heavy

March 2022. We have created a wood workshop and bought a trailer. Now, let’s start building!

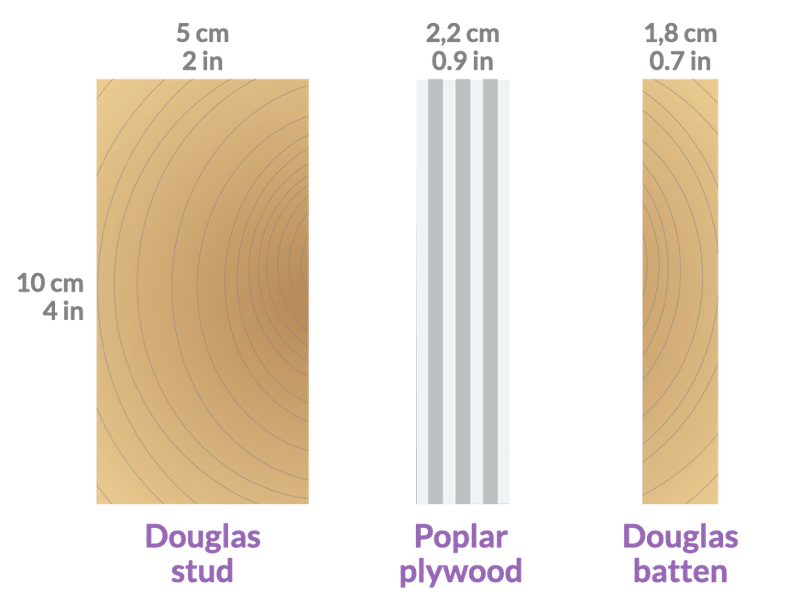

I buy a bunch of 5 × 10 cm Douglas fir studs in the nearby sawmill (2 × 4 in). I like the smell of freshly cut wood, and the owner is kind!

Our tiny house is a sort of cube. I build the 6 faces of the cube independently from each other.

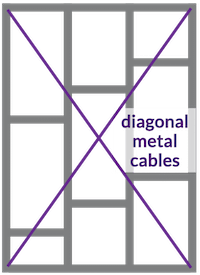

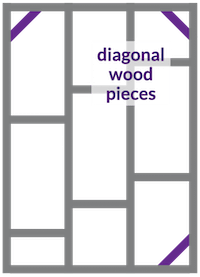

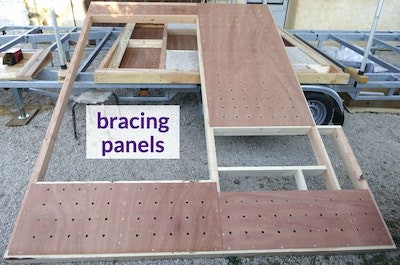

For a wood frame to be strong enough, we need to add diagonal structural pieces called bracing.

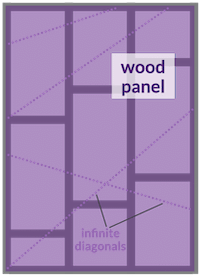

I choose wood panels for Paññā.

When I start to attach the walls altogether, I realize that each one is quite heavy. I can move them on my own, but it does not feel pleasant, or safe. And will I be able to limit the total weight to less than the 3 tons allowed on the trailer?

I start to doubt this strategy.

Developing a lighter wood frame for a tiny house

Should I choose lighter wood, even if it is not local? Or could I use thinner Douglas fir pieces without risking making a too-fragile tiny house?

From time to time, a visitor passes by the construction site and comments on my work. One asks me if I accounted for the weight of the snow in my calculations — hum, I haven’t calculated anything! Another one adds that, according to the norms, cross-bracing panels should be 9 mm thick — mine are 5 mm thick! (0.35 in vs. 0.2 in)

Oops… I start to lose confidence!

Fortunately, with Hsiao, we visit a woodworker, a cousin of my mother. He is also building his own tiny house. He shows us his technique: poplar plywood of 2.2 × 10 cm for the wood frame (0.9 × 4 in), and 3 mm thick panels for the cross bracing (0.12 in). This all looks quite thin.

Amazing!

He confirms that his approach is not standard at all. But he doesn’t doubt: “the resulting structure will be very strong”, he says. That’s exactly what I was looking for! An elegant solution reminding of natural materials like bamboo: although hollow and light, its resistance is often compared to steel or concrete.

I am very excited, but poplar plywood panels are expensive.

After some trials, I choose to use Douglas fir battens instead, of the sawmill. Battens are planks of 1.8 × 10 cm (0.7 × 4 in). Compared to the poplar plywood of 2.2 × 10 cm (0.9 × 4 in), they happen to weigh the same, feel more rigid, and cost 8 times less.

I try to redo one wall with this technique. Wow, I can carry this new wall easily by myself! This way, though, the wall feel a bit more flexible than before.

Is it really going to work?

The intertwined levels of bracing

While continuing, I realize how the structure is being reinforced step by step, in unexpected ways.

The 5 mm (0.2 in) plywood panels clearly rigidifies each wall.

Then, as we screw wood slats diagonally on the structure for the wood cladding, I see they add another layer of bracing.

I identify half a dozen of such mechanisms. The resistance of a construction is a complex phenomenon! So many elements are interacting to create this resistance, at different scales.

Interestingly, when making calculations or following norms, we simplify the reasoning. For instance, we end up installing 9 mm panels (0.35 in), as if they would be the only bracing pieces of the structure. Such simplification leads to a predictable behavior, but may also lead to more material use than necessary.

As a DIY builder, we have the opportunity to choose a more nature-inspired and empirical reasoning, inviting back complexity and multi-functionality. Such an approach increases uncertainty, but it may also increase material use efficiency — and fun!

Eventually, my light wood frame is indeed soberer in materials than the standard version with 5 × 10 cm Douglas fir pieces (2 × 4 in). It weighs two to three times less, and costs three to four times less.

And, is it strong?

After sleeping and working in Paññā for a few months, it definitely feels stable, even under a strong wind. It might be interesting to check how it behaves on a moving trailer.

Actually, the most flexible part unexpectedly happens to be the floor, for which I precisely kept the bigger wood sections of 5 × 10 cm (2 × 4 in)!

The resistance of a construction is a complex phenomenon!

- Previous experiment (11/26) : Literary wanderings

- Next experiment (13/26): A mysterious energetic treatment in Taiwan. Yet, powerful